Diagnostic Tools for Industrial Networks

Measuring plant conditions, detecting sources of malfunction and coordinating maintenance requirements is the top priority of every maintaintence technician. Our essential tools and experienced service team supports you in the maintenance of your automation networks and fieldbus systems. Our wide range of industrial network services extends from documented commissioning measurements up to support for regular maintenance procedures to ensure system availability.

EMC Diagnostic Tools

Measuring Shield Currents

Avoid shield currents and measure for current leakage

Measuring Equipotential Bonding

Prove equipotential bonding according to DIN EN 50310

Intelligent Current Measuring

Detecting and evaluating parasitic currents inteligelllently

Electromagnetic Interferences

Detecting interference currents along fieldbus and cable paths

PROFINET Diagnostic Tools

PROFINET Diagnostic Set

All the essential tools in one set

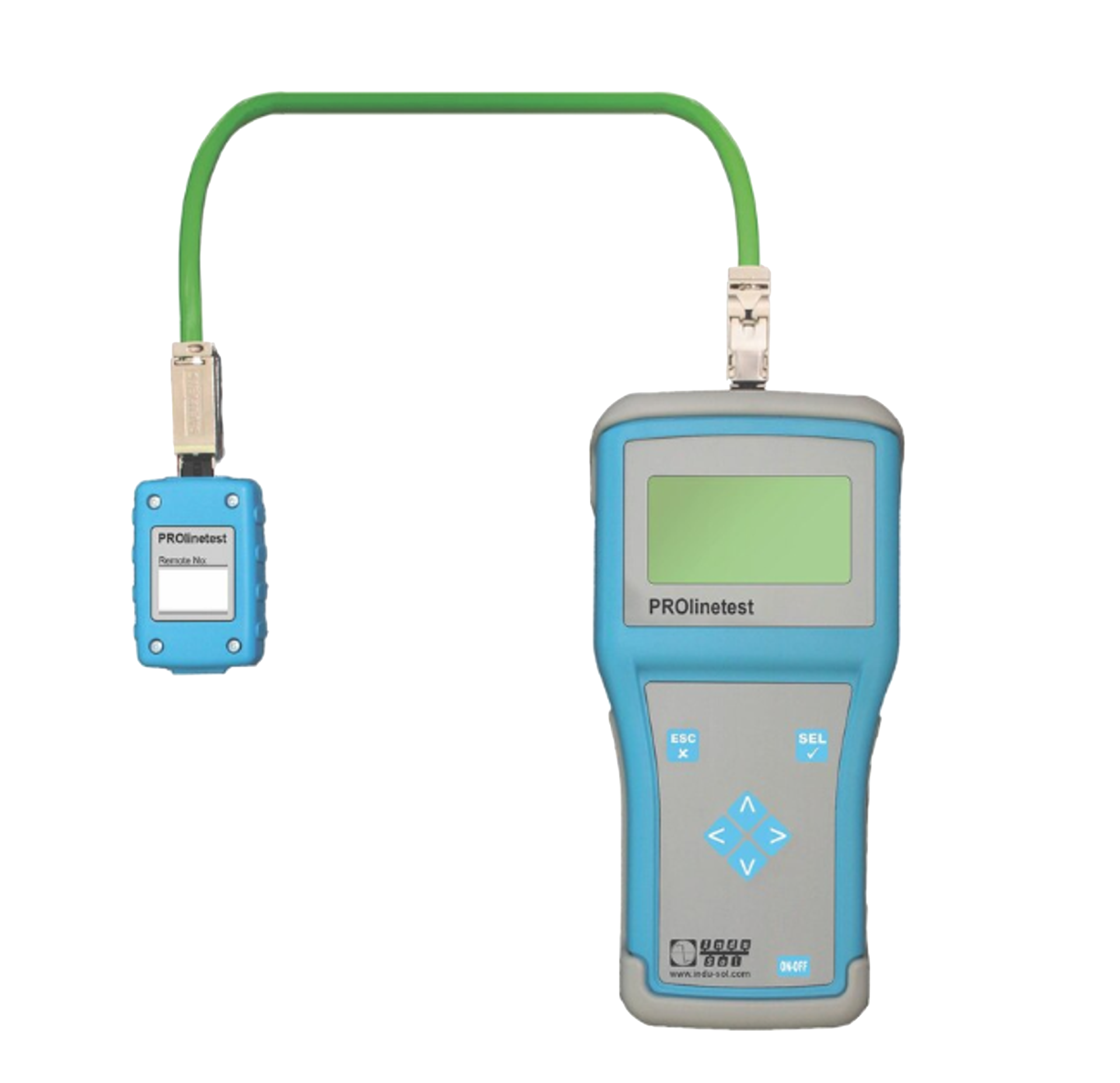

PROFINET Diagnostic Duo

Detecting cable problems to the meter

PROFINET INspektor NT

Intelligent measuring point

PROFIBUS Diagnostic Tools

PROFIBUS Tester PB-Q One

Fast and Precise Quality Diagnosis

PROFtest II XL

For reliable cable test in PROFIBUS

EMCheck LSMZ I

Measuring and avoiding shield currents

PROFIBUS Diagnostic Duo

Online & offline analysis in a set

PROFIBUS Diagnostic Set

All the essential diagnostic tools in one set

PROFIBUS INspektor NT

Monitors the logical data exchange

AS-i Diagnostic Tools

ASi Diagnostic Set

Fast and simple ASi system analysis

ASi View -Tester

Fast and Simple ASi System Analysis

CANbus Diagnostic Tools

Industrial Ethernet Diagnostic Tools

Maintenance instead of repair:

Identify and fix sources of interference in a targeted manner – before problems or breakdowns occur.

Every plant ages. The communication networks of the plants are also affected by this. Whether it’s wear and tear due to use or external influences from the production environment, it often starts with inconspicuous, sporadic anomalies. Since these often remain undetected, the potential for faults can increase and endanger the operation of the plant. But it doesn’t have to come this far!

Network maintenance by external service providers or with your own staff

– It’s not the method, it’s the result that matters

By regularly or permanently checking the communication quality in the plant network, failures can be almost completely avoided. This preventive maintenance (cf. “predictive maintenance”) can be carried out by trained maintenance personnel as well as by external specialists such as Indu-Sol service technicians. When making a decision, it is important to weigh up the respective costs.

- Network maintenance with trained personnel and required equipment

Monitor, control and maintain your plant networks completely independently. The necessary professional training and materials (including suitable measuring equipment) must be available. - Network maintenance by external maintenance service provider

Commission an external specialist with the regular inspection and maintenance of your plant networks. The services vary depending on the provider and the contractual agreement. - Supported network maintenance with your own staff and external support

Relieve your maintenance: Based on maintenance data (thanks to e.g. permanent network monitoring), an external partner supports your maintenance in time-saving fault clearance or maintenance, if required.

Our expert advice: For maximum availability, we recommend regular testing of the communication quality of your network immediately starting with commissioning of the system. These tests can optionally be carried out by your maintenance staff. (Further technical training / suitable measuring equipment required)